Industry in Intralogistics

Facts & figures

Smartlogistix provides specialized intralogistics solutions tailored to the specific needs of each market segment.

Our focus

01. Industrial

In the industrial sector, precision, efficiency, and safety are essential to tackle complex challenges such as production optimization and waste reduction. SMARTLOGISTIX solutions streamline processes, improve resource management, and reduce downtime.

Automation accelerates internal handling, ensuring continuity and real-time traceability of materials and components. Predictive analysis prevents failures and delays, enhancing maintenance and plant efficiency. Inventory and space optimization reduces costs and improves warehouse management.

Workplace safety is enhanced by reducing manual handling. SMARTLOGISTIX provides concrete tools to boost productivity and competitiveness in the industrial sector.

02. Food & Beverage

In the Food & Beverage sector, speed, safety and compliance are fundamental. SMARTLOGISTIX solutions optimize production and logistics flows, ensuring supply continuity, waste reduction, and maximum hygiene at every stage, from production to packaging.

Digital management allows real-time control of operations, synchronizing production, storage, and distribution. This improves responsiveness to demand and reduces waiting times, preserving product freshness. Internal automation accelerates goods handling, optimizes space, and increases order processing capacity.

An integrated, efficient, and secure system for a lasting competitive edge.

03. Automotive

In the automotive sector, efficiency and precision are crucial to ensure quality and competitiveness. SMARTLOGISTIX solutions optimize production and logistics flows, reduce downtime and improve internal management, ensuring operational continuity and flexibility.

The integration between production and logistics enables real-time monitoring, optimizing resources and interdepartmental coordination.

This results in less waste, more effective maintenance, and proactive management. Material handling becomes smoother and safer, with fewer errors and increased productivity. Inventory and storage spaces are automated, ensuring constant availability and traceability throughout the entire supply chain.

04. Chemical & Pharma

In the chemical and pharmaceutical sector, internal management requires the highest precision and compliance with strict safety, hygiene, and traceability standards. SMARTLOGISTIX solutions provide full operational control, reducing contamination risks and optimizing time and resources.

Advanced automation ensures sterile environments and faster, safer processes. Real-time monitoring enables batch traceability in accordance with GMP regulations and ensures data security.

The integration of production and logistics systems enhances synchronization between departments, reducing waste and increasing productivity. Digitalized inventory management ensures consistent material supply, improving responsiveness and competitiveness in a highly regulated market.

05. Paper & Nonwovens

In the production of nonwoven, tissue, and paper, efficiency and continuity are essential.

SMARTLOGISTIX solutions optimize the transport of raw materials and the handling of mother and finished reels, reducing delays and increasing productivity.

Real-time monitoring and digital process management enhance operational coordination, reduce downtime, and improve safety in handling operations.

Automated storage optimizes space and ensures quick material retrieval. SMARTLOGISTIX automation reduces manual work and waste, increasing reliability and efficiency. Companies can thus maintain high production standards and respond swiftly to market demands.

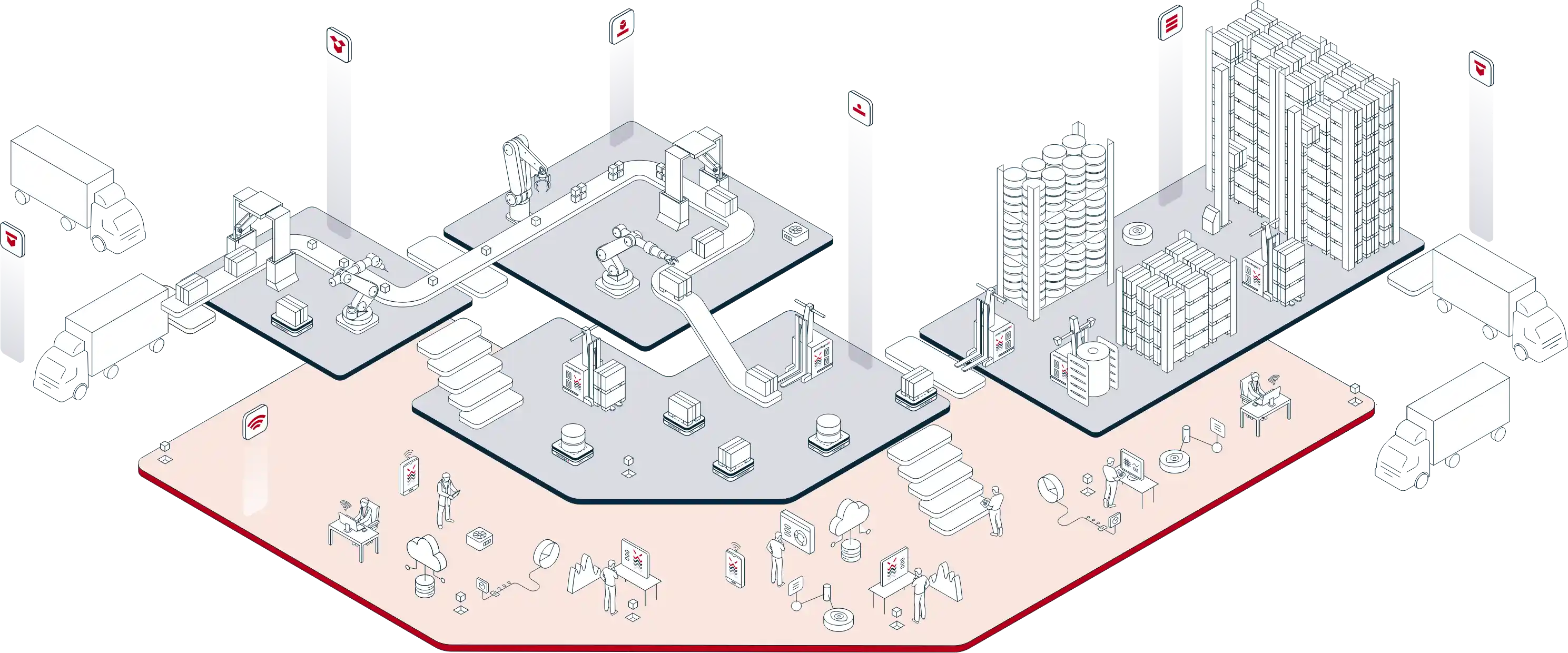

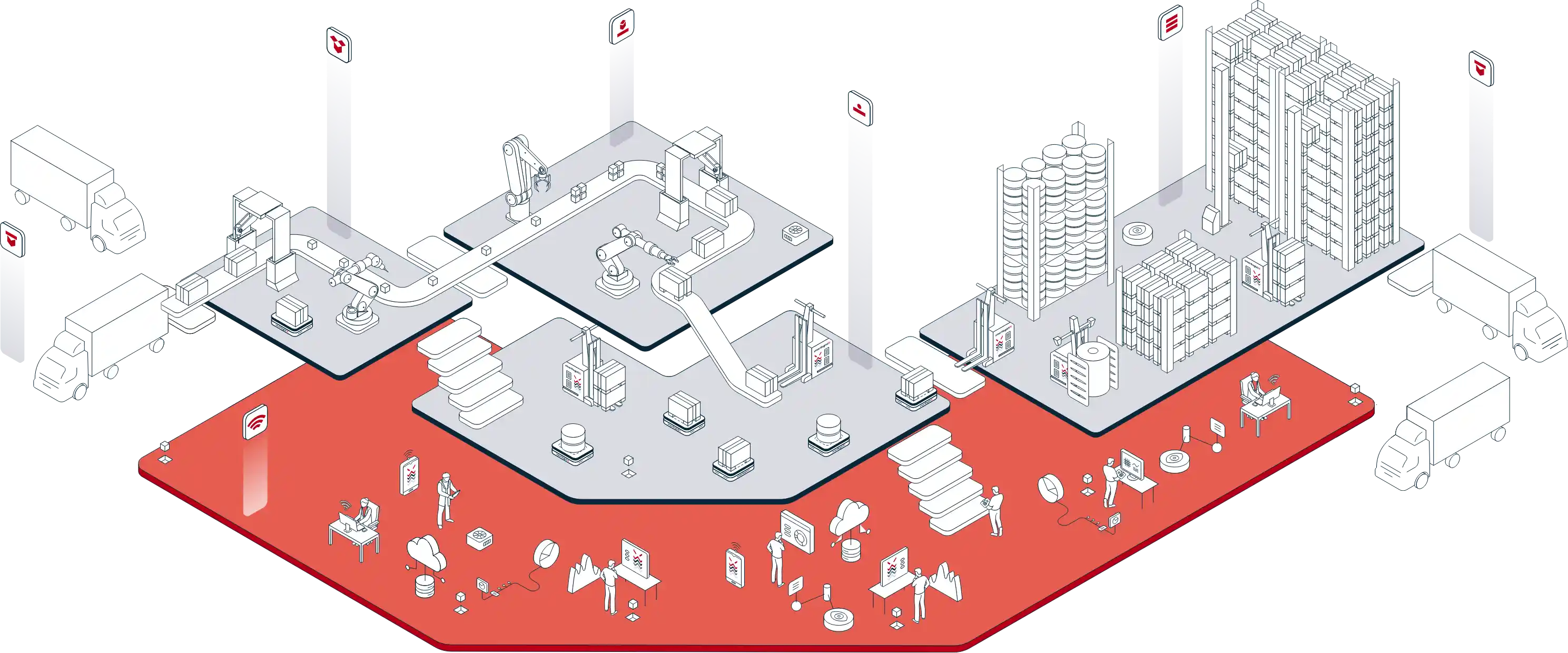

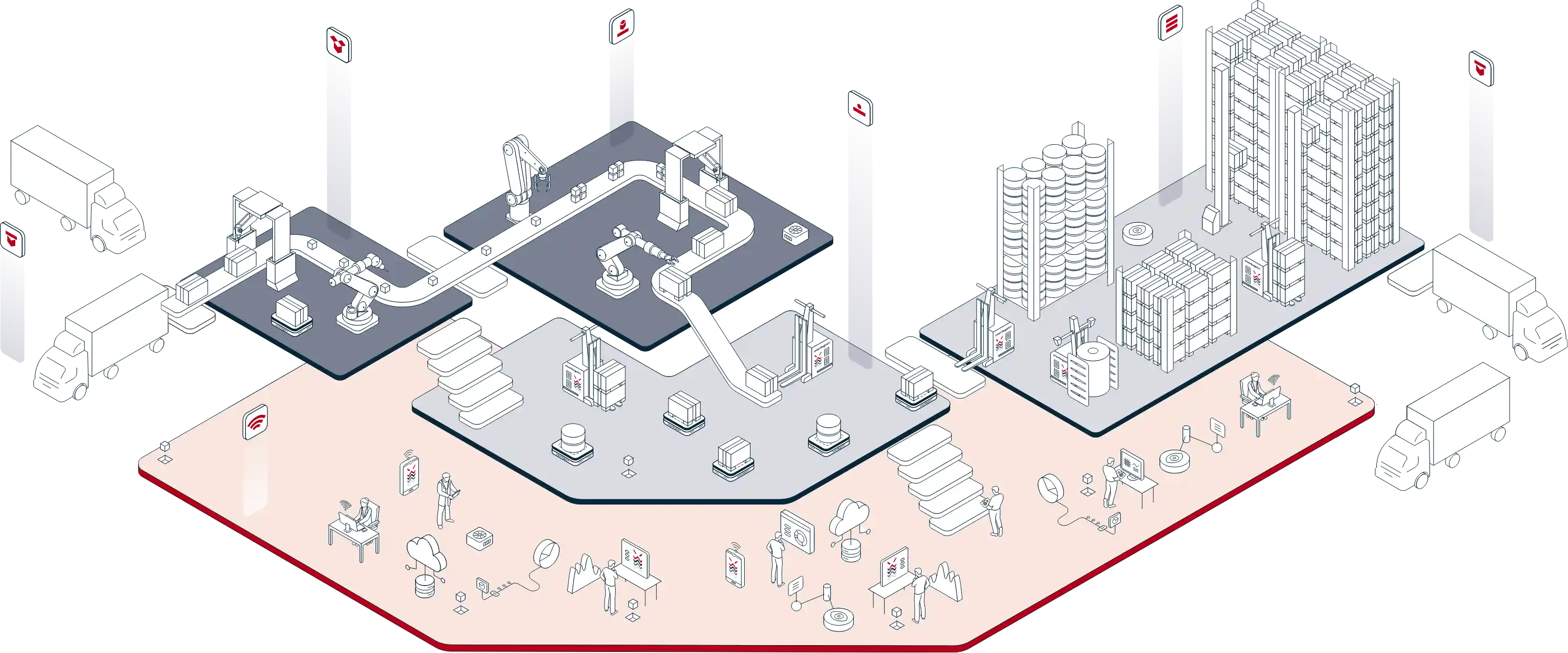

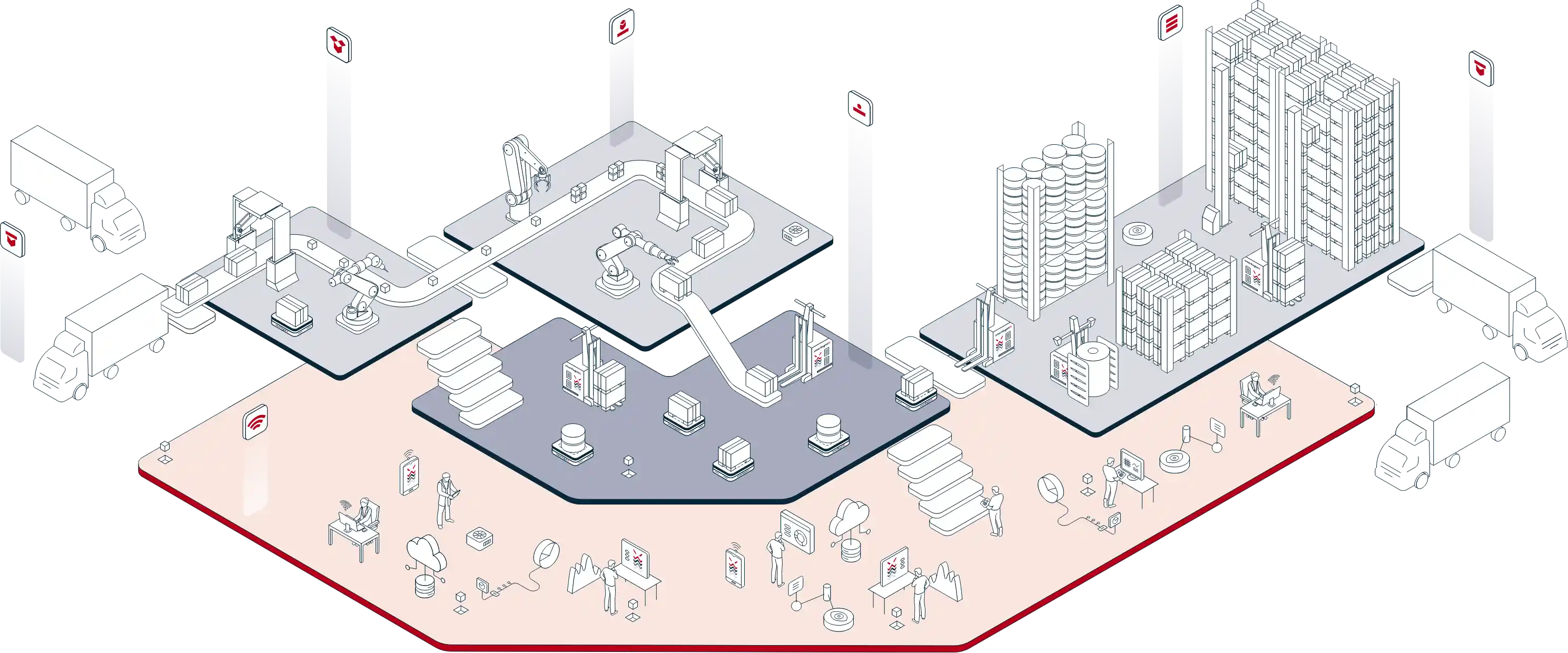

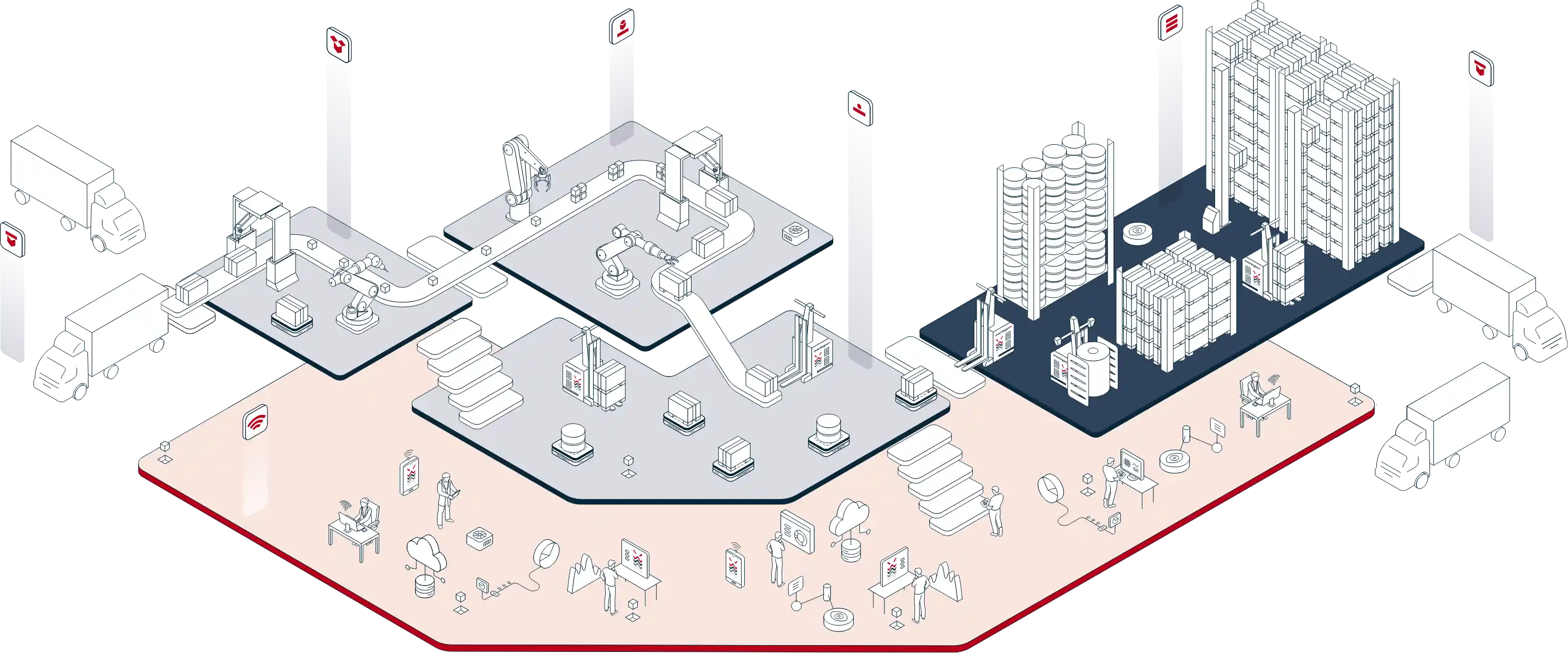

The Smart Factory

With a view to the development of Smart Factory systems, Smartlogistix provides integrated systems dedicated to the industrial automation and intralogistics sectors. We offer hardware and software solutions capable of automating and digitizing production processes, in order to optimize the management of handling, transport, and storage of raw materials, semi-finished products, and finished products flows.